High investments and operating costs, the precise coordination of a large number of processes and the reliable provision of teams of highly qualified employees - these challenges characterize the OR department as the high-performance engine of the hospital. A disruption of the processes in the OR usually leads inevitably to painful idle costs and loss of revenue. The smooth and plannable coordination of OR processes is the central success factor for every somatic hospital.

Why are process optimization measures not consistently implemented in hospitals?

The symptoms of the disruptions are usually known to those involved in all areas of the clinic. Nevertheless, the analysis of the actual reasons, the measures to be derived and the responsibilities are often controversially discussed by the departments and prevent a focused change of the clinic processes for the better.

- Lack of an overall view: Today, modern surgical systems provide a high degree of documentation and thus an extensive database. However, it is often not possible to consolidate this data in the analysis on a clinic-wide basis. The end-to-end view of the key figures is missing.

- Lack of a factual basis: The objective factual basis is often missing, with the help of which process sequences and breaks can be presented transparently by measuring verifiable time stamps.

- Lack of focus: Complex process recordings waste time without the result being a transition of concrete measures into a sustainably controlled implementation process and thus supporting ongoing monitoring.

Process Mining: Using verifiable figures to uncover process potentials and generate objectivity

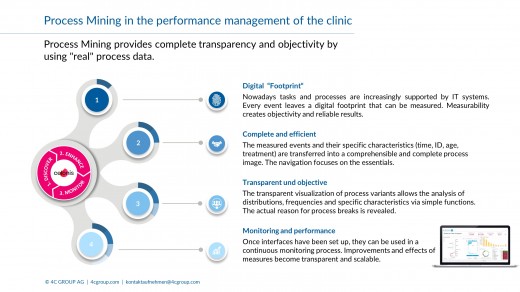

Process Mining, as a Big Data technology, offers a proven platform that illuminates process potentials with verifiable figures and transparent process images. Existing process data is extracted from information systems and actual processes, such as patient throughput times, the occupancy of operating rooms or the distribution of medication, are reconstructed based on real-time data. Analysis tools allow to extract and understand the reason for process interruptions by means of objective, unchanged measurement data (digital footprint).

In which hospital areas can Process Mining be implemented?

In addition to well-known focus areas, it also deals with areas that could not be successfully solved in the past, but which can quickly become a success and operational risk of a clinic or hospital in phases of high workload and capacity utilization as well as in the shift of the treatment spectrum combined with high quality and process requirements:

- Operation Room Management - How can we better measure and improve the situation-oriented utilization of operation rooms?

- LOS Management - Are there additional approaches to reduce the length of stay of patients?

- MD Audits - How can we make billing processes audit-proof and more automated?

- Administration - Is there a way to create an overall view of central processes that allows us to identify approaches for eliminating disruptive factors in daily operations?

- Controlling - How do we manage decided improvement measures in such a way that improvements in day-to-day operations are noticeable and measurable in the figures?

Why 4C? - We offer you hospital expertise combined with the right technical solution

Our healthcare experts have extended their more than 15 years of experience in hospital management by the innovative Process Mining technology and, together with the market leader Celonis, have established a new professional and technologically driven approach to increase value in hospitals. Through our partnership, we therefore not only offer you the right technical solution, but also the corresponding expertise in hospital management.